Page 6 - ALWAco SPP Brochure

P. 6

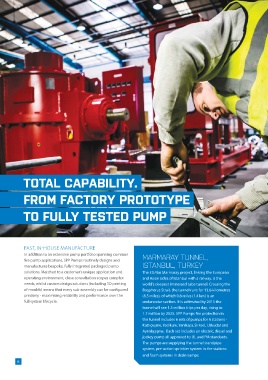

TOTAL CAPABILITY.

FROM FACTORY PROTOTYPE

TO FULLY TESTED PUMP

FAST, IN-HOUSE MANUFACTURE MARMARAY TUNNEL,

ISTANBUL, TURKEY

In addition to an extensive pump portfolio spanning common

fire pump applications, SPP Pumps routinely designs and The £3.4bn Marmaray project, linking the European

manufactures bespoke, fully integrated packaged pump and Asian sides of Istanbul with a railway, is the

solutions. Matched to a customer’s unique application and world’s deepest immersed tube tunnel. Crossing the

operating environment, close consultation scopes complex Bosphorus Strait, the tunnel runs for 13.6-kilometres

needs, whilst custom design solutions (including 3D printing (8.5 miles), of which 0.8 miles (1.4 km) is an

of moulds) means that every sub-assembly can be configured underwater section. It is estimated by 2015 the

precisely - maximising reliability and performance over the tunnel will see 1.5 million trips per day, rising to

full system lifecycle. 1.7 million by 2025. SPP Pumps fire protection in

the tunnel includes 6 sets of pumps for 6 stations -

6 Kazlıçeşme, Yedikule, Yenikapı, Sirkeci, Uskudar and

Ayrılıkçeşme. Each set includes an electric, diesel and

jockey pump all approved to UL and FM standards.

The pumps are supplying the tunnel standpipe

system, pre-action sprinkler system in the stations

and foam systems in drain sumps.